Premade Pouch Packing Machine

Automatic Dried food nuts weighing and packing machine

- Title: Automatic Dried food nuts weighing and packing machine

- Type: Multi-function chips weighing and packing machine

- Pouch pattern: Stand-up, Flat, Zipper Bag

- After warranty: Video technical support, online support, spare parts, field maintenance and repair service

- Description: AUTOMPACK-Dried food weigher,Dried food packing machine,dried food packing machines manufactuer

Automatic dried food Nuts Weighing And Packing Machine

Application: Automatic premade pouch bagger, featured with rapid reaction, reliability and quick changeover, is ideal for a large variety of bag types and range. Equipped with Auger filler and Auger elevator, it is widely applied to different kinds of Powders

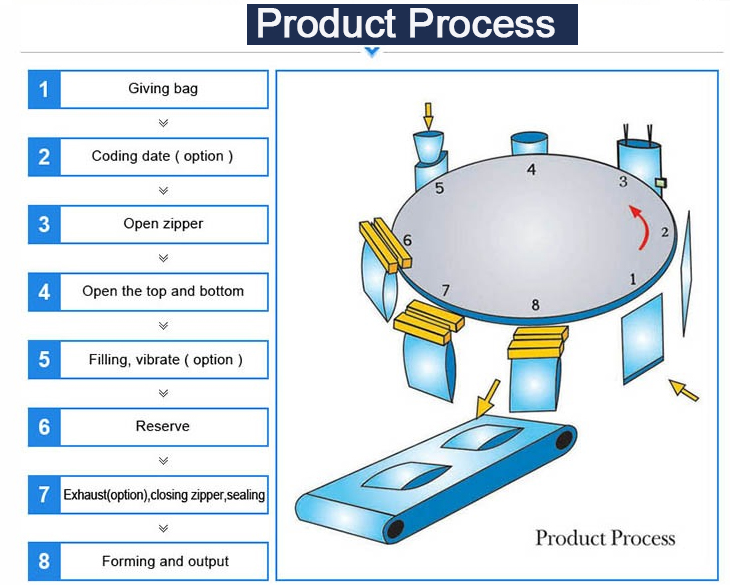

Models and Processes:ATM-8200/8250/8300 series premade pouch bagger can be clarified into 8 working stations and 6 working stations in terms of station amounts in one machine. Specifically, the whole processes are involved in the following stations:

1- ➣Pouch-picking Station (Required)

2- ➣Date-printing Station (Required)

3- ➣Pouch-opening Station (Required)

4- ➣Material-filling Station-1 (Required)

5- ➣Material-filling Station-2 (Optional)

6- ➣Air-exhausting Station (Optional)

7- ➣Material-detecting Station (Optional)

8- ➣Sealing and Outputting Station (Required)

Process Map for Baggers with 8 Working Stations:

Notes: Required Station is necessary to complete the package. Optional Station is made as per customer’s request, such as zipper-opening device, dual dosing systems, dual sealing configurations, gas flushing device, air exhausting device, and so on.

Pouch Type:

All type of heat sealable preformed side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout etc.

According to the picture you provided, you have to choose 8 working stations:

✉E: info@autompack.com ☎ Tel: +86-757-6395 2051 WhatsApp: +86 17727327291

Interested in this machines? ▶▶▶ Get a Free Quote

Categories

LATEST NEWS

- Perfect for liquid, coffee and2020-12-12

- In-stock packaging equipment i2021-04-12

- Simple, Efficient Packing Mach2018-07-30

- How to convert a semi-automati2018-07-08

- Solutions to common problems o2020-12-25

Contact

CONTACT USContact: Dennis Wong

Phone: +86-757-6395 2051

Whatsapp: autompack

Email: info@autompack.com

Add:6th floor, Workshop No. 4, Lane 2, Dazhuang Road, Lijia Development Zone, Shangan Community, Danzao Town, Nanhai District, Foshan city, Guangdong, China.